What if the box hadn’t been invented?

Pretend that the cardboard box had never been invented, and you have to move. You gather up your stuff a handful at a time—socks, spoons, pillows, toys, etc. Maybe put some of it in bags, carry it an armful at a time to your car, lots of trips. You drive to your new house, pick it up an armful at a time, and unload your car.

That is exactly what shipping was like before the sea shipping container was invented. Individual pallets, bags, and boxes moved by hand in and out of ships, trains, and trucks. You can move that way, and it works, but moving with cardboard boxes is a lot easier and more efficient. The container is so much more efficient that freight rates and loss dropped 90%. Suddenly, you can ship things economically, and the whole world opens up.

Now, pretend the cardboard box has been invented, but it can only be picked up or taken out of your car with a special crane that you have when you leave and where you arrive. It is a lot easier to load your stuff into the box and into the car, but you can’t unload any boxes until you get to the other end, where you have another special crane. That is what is happening now with sea shipping containers.

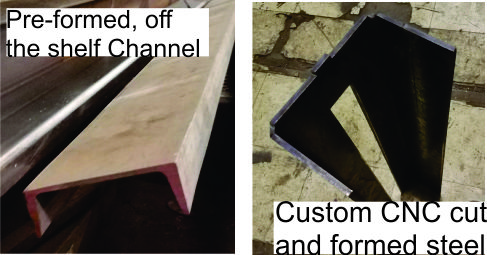

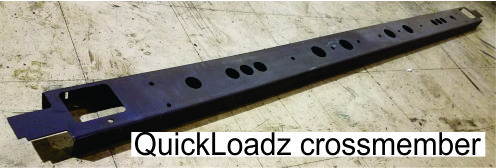

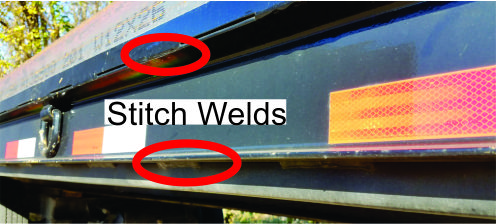

Until some guy in Ohio invents a way to pick up and drop off cardboard boxes whenever and wherever you want, without the special cranes at either end—way easier. Now that you can pick up and put down your cardboard boxes wherever you want, things like UPS and Amazon suddenly become possible. It’s exactly the same with sea shipping containers. Some guy in Ohio invented QuickLoadz, which picks up and puts down sea shipping containers wherever you want, without any cranes. Same benefits, just bigger boxes. Warehouses, ports, and loading docks will be a lot less important as containers move end to end wherever you want. What else will suddenly become possible?

Great book on how the box changed the world: