QuickLoadz Launches Second Reg CF Campaign on Republic!

Exciting times are upon us as we redefine the world of freight. Today, the QuickLoadz team is thrilled to announce our second Reg CF round on Republic! We’re opening the doors for EVERYONE to acquire a stake in our company.

Innovation 50 Years in the Making

For the past 50 years, intermodal freight has been largely unchanged relying on expensive, fixed infrastructure for container movement. This long-standing inefficiency not only inflates costs but slows the global economy. With more than 600 million ISO containers moving worldwide annually, there needs to be a better way to move sea shipping containers to reduce delays.

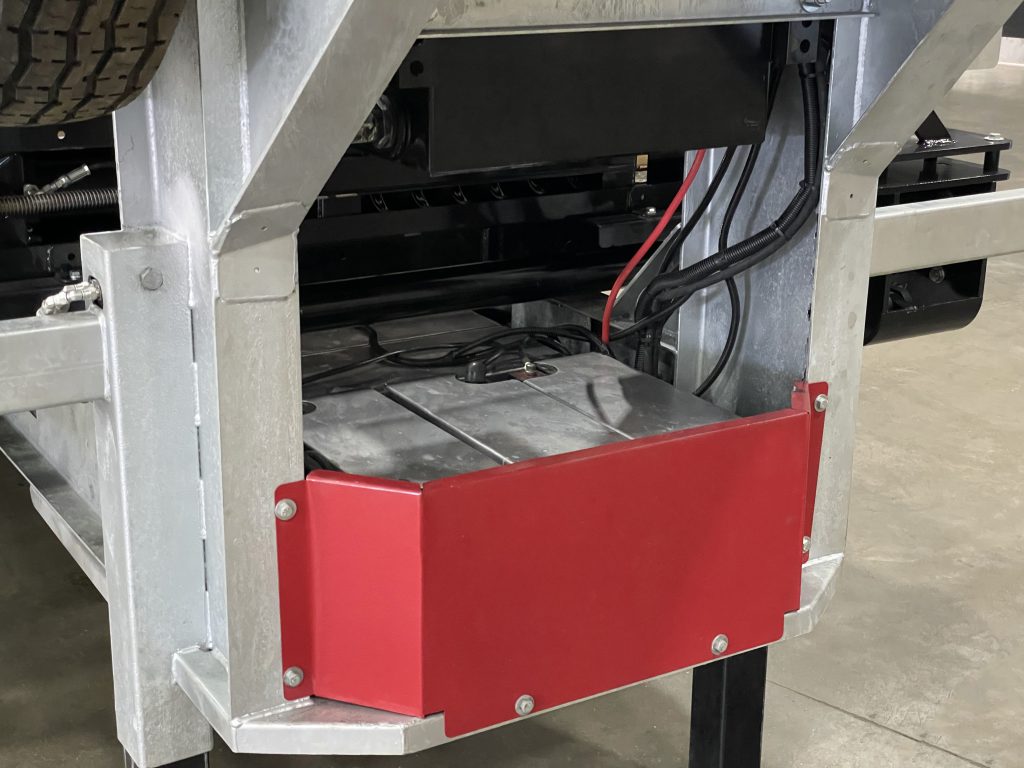

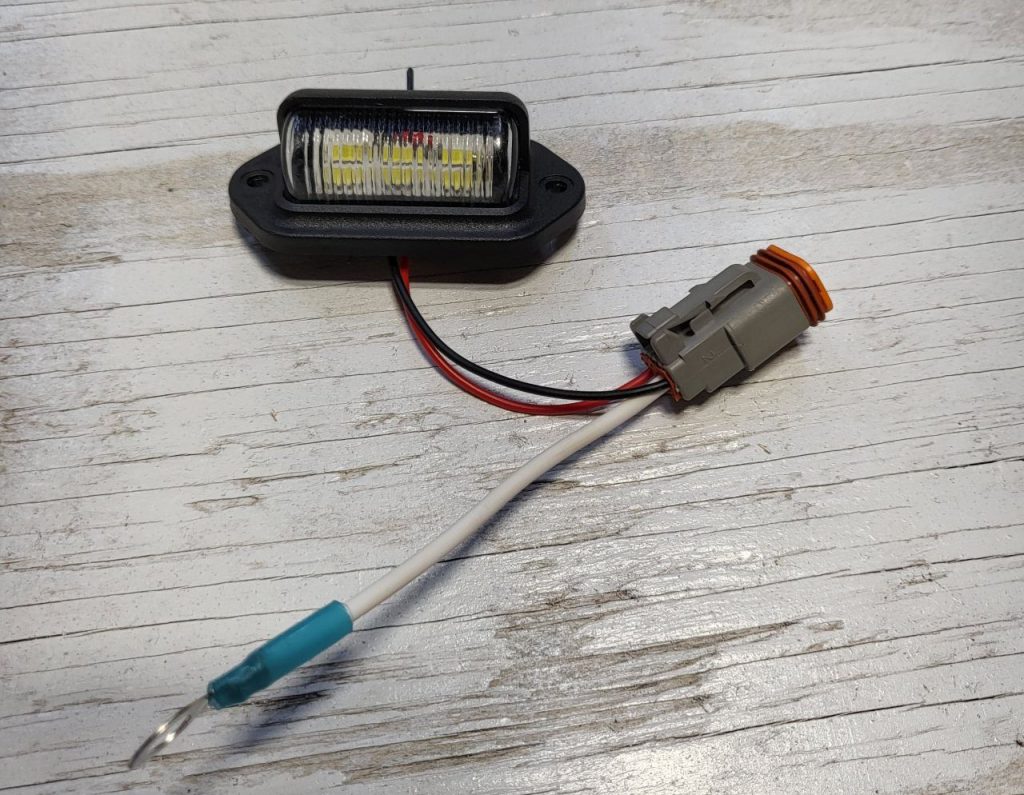

QuickLoadz introduces a paradigm shift with its revolutionary smartphone-controlled trailers. Engineered to move shipping containers faster, safer, and more efficiently than ever before. The innovative system eliminates the need for expensive loading docks and cranes. Drivers can now remain seated throughout the entire process, significantly enhancing overall efficiency and productivity. Now, a container can be loaded or unloaded in 3 minutes with the tap of a few buttons.

Goods and materials must be 4ft off the ground, waiting to load or unload. Transport drivers wait anywhere from 3 hours to 3 days to unload at a loading dock. QuickLoadz reduces that time to 3 minutes! On average, only 1 in 20 container chassis is in transport. The other 19 are sitting, waiting to load or unload. That means 95% more container chassis need to be licensed, maintained, insured and managed compared to one QuickLoadz.

Company Highlights:

- Revenue $10M to date; Est. ’24 Rev = $15M

- QuickLoadz is global: exports comprise 20% of 2023 sales, QuickLoadz has attracted licensing inquiries from the EU and Asia

- The company’s direct sales model reduces standing inventory

- Global patents

- Product ease of use, safety, creates savings and immediate ROI

- Innovative logistics tech: Solves port congestion, final-mile distribution

- QuickLoadz is in the hands of customers now: thousands of containers getting moved all over the world by QuickLoadz

- Revenue to date +$10M

- 2024 LOI for 100 units from Horizon Motor

- Winner of numerous awards, most recently Amazon Small Business Grant winner

- Enterprise interest for 1,000 unit orders

- Customers include the US Army, United Van Lines, United Rentals, and Irby Utilities

Investment Highlights:

- Acquisition target for defense, logistics, global retail industries, in talks now

- Triple-bottom line: solar/battery electric (EV), humanitarian aid

- Huge $9.6T TAM

- Operating high margin high revenue business with $5M in facility

- High barriers to entry for competitors

- Last QuickLoadz CF raise top rated by King’sCrowd independent reviewer of CF raises.

Own a Piece of QuickLoadz for as little as $100!

Head over to our Republic campaign page for an in-depth look at the opportunity and dive into the specifics of our Reg CF campaign. But don’t keep this excitement to yourself – share the news with your network and social media followers!