Imagine that you had the time, experience and resources to build, rebuild, refine, work a trailer to simply, safely do its job perfectly. That is what QuickLoadz is. At QuickLoadz, we move containers every day—empty, loaded. We have customers all over the world talking to us giving constant feedback.

At QuickLoadz we have the time, machinery, money, and experience to build the perfect trailer for moving sea shipping containers. So we do. We don’t build any other kind of trailer.

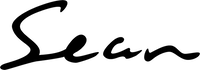

At QuickLoadz, design is everything. We build our trailers with CNC cut and bent sheet steel instead of off the shelf channel, and beam steel.

What do I mean by custom cut and bent flat steel vs off the shelf pre-formed steel? Preformed steel comes in specific sizes and is formed at the steel mill. Design is limited to what you can do with those sizes.

With custom cut and bent steel, design is not limited to what you can buy off the shelf.

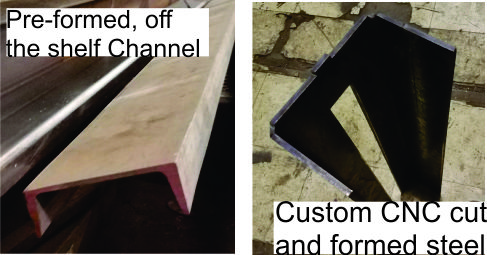

Holes for hoses, wiring, bolt placement are exactly where you want them, what size you want them, and exact as only a CNC cut and bend can create.

You can create almost any shape you need, in almost any dimension you need. If you need a Z beam at 5 3/16” to make everything fit perfect, you have it.

Not only are perfect custom shapes easy, change is easy. You discover that if you make a beam 1/2” wider, then you can add a feature. Done.

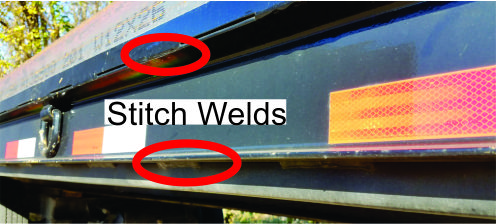

With custom cut and bent steel, you don’t need stitch welding.

Most trailers are constructed with off the shelf channel, angle, and I beams. In trailers, these off the shelf steel channel are not welded the entire length for good reason. If you continuously weld, then you fight warping the steel with heat. For a 40’ trailer, you would end up welding hundreds of feet of steel—just for the side rails. Instead, side rails are stitch welded.

Stitch welding means that instead of welding along the entire length where steel beams come together, they are just welded in places. Often times, between welds is filled in with caulk to try to stop water infiltration. With stitch welding, you also introduce heat stress. If you stitch weld 2 pieces of steel together, it is not nearly as strong as if it were one piece of steel. Under continuous flexing, it will crack at the welds.

At QuickLoadz, our side rails are one continuously bent piece of steel. No heat warp, no heat stress, no stitch welding; just a strong, perfectly shaped piece. Lighter, stronger, no gaps for water to sit and rust to form.

QuickLoadz trailers are built to last, with every single part of the design carefully considered.